(Grab an old sponge - yes, seriously)

I have a Canon Pixma MG5750, a Currys PC World purchase when I needed a cheap multifunction printer fast. Handy at £45 (another set of genuine ink for it costs the same, go figure). I never expected it to be perfect, I assumed it would at least be able to reliably accomplish basic things like print text onto paper.

Unfortunately, one of the fundamental printer requirements - loading its own paper during print jobs - was a little lacking with this unit. Research indicates it's sadly a common issue with this range of Canon printers.

Soon after buying mine, the paper feed (take-up of paper from the tray into the transport mechanism) started to behave irregularly. Soon after that, I ended up having to nudge each sheet of paper in to the printer, it was unable to take in paper itself. Not convenient.

I put up with this for a while but an attempt to print some documents evening pushed me into investigating. The fix, as it turns out, is really simple!

The Canon MG5750 (and printers of its ilk) are designed to a price, and that is cheap. All components are nylon and plastic where possible, plastic is flimsy and important components like springs are small and presumably old stock - and this was ultimately the root cause of my problem.

- The symptom: the printer would be unable to take paper in, meaning it would sit and spin its internal rollers helplessly several times before complaining there was no paper loaded.

- The cause: a tiny spring, intended to load the paper intake rollers, is inadequately weak. The intake / feed-in rollers just slide around on top of the paper instead of gripping it and pulling it into the print mechanism.

- The solution: a bit of sponge (seriously).

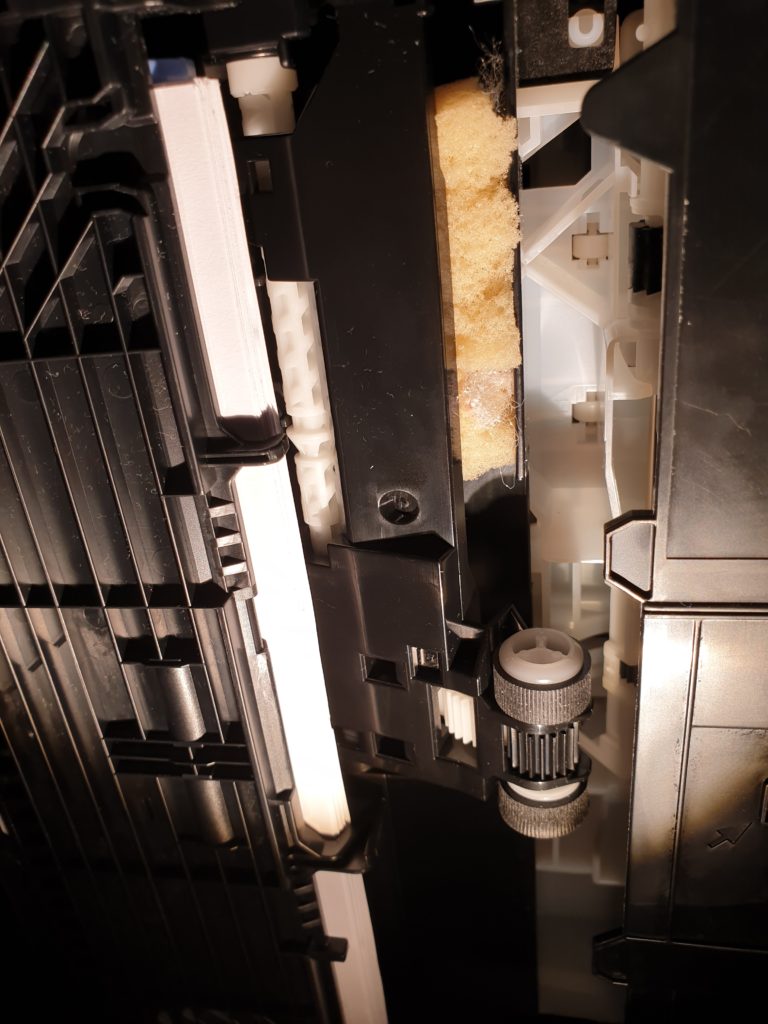

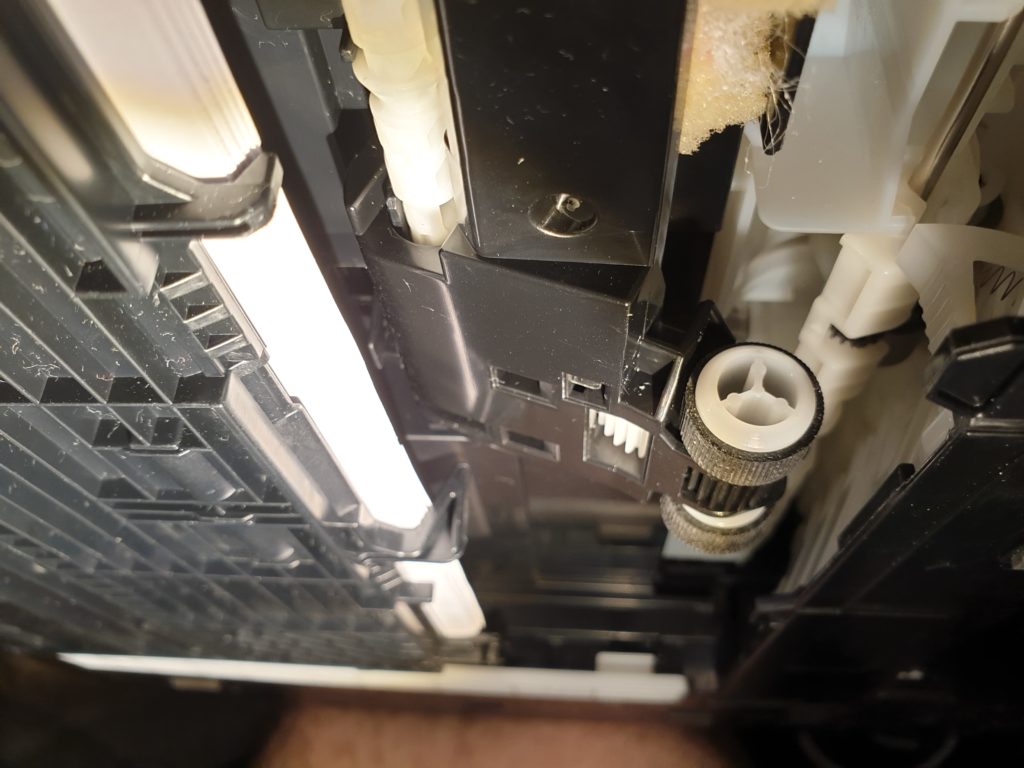

This is the underside of the printer. The paper tray forms the base of the printer when it's slid into place, the grey strips are its guide runners. (view larger)

This is the underside of the printer on its side with the paper tray partway open.

What should happen: When you slide the paper tray closed, the black tab at the top of the image (just above the bit of blue plastic you can see against the paper) contacts a protruding black plastic 'leg', which pushes the infeed roller arm up and over the paper as it's inserted. (view larger)

This would be fine, if the retaining spring's opposing force was strong enough. It's a miserably tiny thing. See it near the middle of the photo, just next to one of the two black rubber paper intake rollers? (view larger)

I tried all sorts - wrapping the rollers with small strips of tacky gaffer tape to widen their diameter; pushing up on the underside of the paper tray to try and make them contact the rollers better; I even moved the rubber tracks towards the edge of the wheels to make their edges 'ride up' and contact the paper better. Nothing worked well.

In the end, some sponge (visible behind the bar supporting the feed rollers) solved the problem! (view larger)

Before I used the sponge method, moving the grippy rubber bands to the edge of the grooves on the rollers worked, proving it was a simple issue of roller clearance, but it's not ideal. You end up stretching the rubber tracks around the feed rollers, wearing them smooth prematurely and ending up with catastrophic loss of grip, just like excessive camber on F1 cars (ha).

There's nothing really you can adjust with these printers; the tension spring was just not good enough to adequately pull the rollers down into contact with the paper. So I went to the Internet for inspiration because I knew I wanted to somehow either add weight to the horizontal bar on which the rollers were mounted, or increase the spring tension.

I wanted to avoid removing the tiny tension spring, because they frequently fly off into another dimension, and fortunately I stumbled upon a post by David Camm on a TechAdvisor forum thread:

Hi Folks, this is an asy fix, get a sponge, I used the sponge off a dish scourer, you only need half of that, cut it off the scourer part.

Now find the paper feeder roller that takes the paper from the tray. (its under the printer behind a panel that has the paper in. You will notice the feeder roller attached to a plastic panel that moves up and down to grip the paper, this roller has a small spring on the side. I noticed there is hardly any force pressing the roller to the paper, hence the problem.

Put the sponge behind the piece of plastic away from the rollers taking care not to put it behind the actual rollers. This increases pressure on the roller so it takes the paper every time. just done 150 double sided sheets with no problems. Make sure the plastic holding the roller still moves up and down freely, the sponge should not be so tight as it prevents free movement.My MG550 had this issue from new as well but this spong has fixed it. Its very simple to do.

DavidCamm on TechAdvisor

I realised that, as long as you fitted correctly-sized pieces of sponge snugly, and underneath the part of the bar closest to the tray slide rail (and without it catching in the rotating arm which drives the rollers), this is a beautifully neat solution which solves the problem.

An old Dishmatic head was just the right dimensions and with enough pushback thanks to its top layer to give the rollers adequate friction. Any medium density foam or sponge should work fine.

So thanks, David Camm, wherever you may be! You solved my frustrations and prevented me taking apart my printer in desperation to try and fix. Sometimes the stupidly simple solutions are the best!

I recently found that 'Beach Badger' tried the sponge fix with success - check his video on YouTube demonstrating how quick the fix is, or see below:

'Helen Spuddulike' also made a video demonstrating another method for cleaning some of the other internal rollers, involving some adhesive tape on a longer piece of cardboard. Her method has the advantage of allowing feed rollers to rotate and effectively self-clean while avoiding disassembly, which could be useful if you're getting dirty marks or ink stains on your paper:

'IONHowTo' also has a useful video compiling a few things to check and maintain on printers -- and what not to try (his demo printer is a Canon, but may be useful for owners of other brands):

These easy but non-obvious foxes do make me wonder how many people have thrown away an otherwise functional printer, just because the roller and tension spring design isn't fit for purpose. I'm really glad that so many people have had success and got their printers back in service, and I really appreciate people commenting and emailing me to let me know 🙂 On behalf of our planet, thank you for not throwing your printer in the trash!

Best thing about this fix is that it's trivial to reach the area once the paper 'cassette' is slid out, and it's easily reversible should you decide you don't want sponge there any more. Prop the printer on your knee on its side and just add the sponge pieces as needed. I went for two rectangular pieces. Secure the sponge with gaffer tape if you're feeling nervous, but it should be fine there forever.

Happy printing!

Thank you a thousand times. The sponge trick worked for me. Cleaned the rollers and that worked for about eight papers then, in desperation, tried the sponge trick. B*** marvelous. Have printed 100 pages without a problem. Thanks again.

Another printer saved from landfill, which is always good news. Now all we have to do is find reliable ink which doesn't cost a month's wages... Thanks for the comment 🙂

I've got a CISS (Continuous Ink Supply System) on mine. Far cheaper to run.

https://www.cityinkexpress.co.uk/ciss

Nice, I was weighing up a printer with a CISS last time but realised my print volume is nowhere near adequate for an external CISS, and knowing my luck mine would leak everywhere... Canon OEM cartridges for the time being! What printer have you paired your CISS with?

Who are you and How do I find you? I just located you online while searching how to fix my printer; but, I have given up and found one that is similar at WalMart. I am 75 years young and not quite as agile as I used to be nor patient.

So I wanted to drop you a line and let you know I appreciate your hard work and would like to know how to access you in the future, if possible.

Thank you,

Becky

Hi! I'm Chris and I live in the UK. Message received - appreciate you dropping me a line and if you want to get in touch in future, you can get my email address from the Contact page. I've also dropped you an email to the address you supplied on your comment. Cheers! https://chriswoods.co.uk/contact/

I really wish I'd found this years ago.. we've printed Masters Theses, GCSE projects, legal letters etc one bleeping page at a time for about 6 years now XD. Unfortunately the reason that brought me to your page was another common PIXMA fault which I think is terminal this time. The print head under the largest reservoir (PGBK) is so far out of alignment that none of the vertical tests on the alignment test get rid of the lines - and they are also keystoned (for those of you who have struggled with old CRT's or projectors you may know what I mean) so that the bottom of the test strip may align but the top is about 2-3mm out! I've tried a manual realignment but it's so bad nothing works any longer - tried a manual clean of the head, a number of catridge reseats, different cartridges, OEM, aftermarket etc. No joy 🙁 I think this Printer is for the recycling pile.

Oh dear, that sounds a little more terminal - if you are reconciled to WEEEing the printer in the worst case, I'd propose a careful disassembly to see if anything's stuck in the printhead mechanism, and scrap it if it's unfixable. Might yet be repairable? When I took apart my last (Epson) printer, it never quite reassembled properly afterwards 😉

Genius! Years of misery solved in under a minute.

Can't thank you enough.

Hive mind of the Internet comes together to cure a problem once again 🙂

This helped. Thanks

Thank you for this video. Life saver!

Thank you so much for this! <3 My old Canon Pixma MG5550 stopped eating paper just when I was supposed to print all my Christmas cards, super annoying timing, but I googled and found your blog and this crazy little sponge trick worked! Amazing, big thank you, I hope you have a great Holiday season! 🙂 Greets from Finland!

Likewise, very glad to have helped save your sanity just in time for Christmas. Greetings from the UK 🙂

Thanks so much!

This was driving me spare!

Really appreciate your taking the time to post this simple and easy (and so far 100% successful) fix!

Cheers

Rod

Hi Rod, It's still working for me a couple of years on so hopefully will work for you for a long time yet. Thanks for the message. Cheers, Chris

Thanks so much for posting this solution. It worked for my MX492. I cleaned the rollers (both the feeder rollers and the transport rollers) too. Whew! Happy 2024!

Hurray! Happy days, thanks for letting me know it worked for you. Is the MX underside design similar to the MG series?